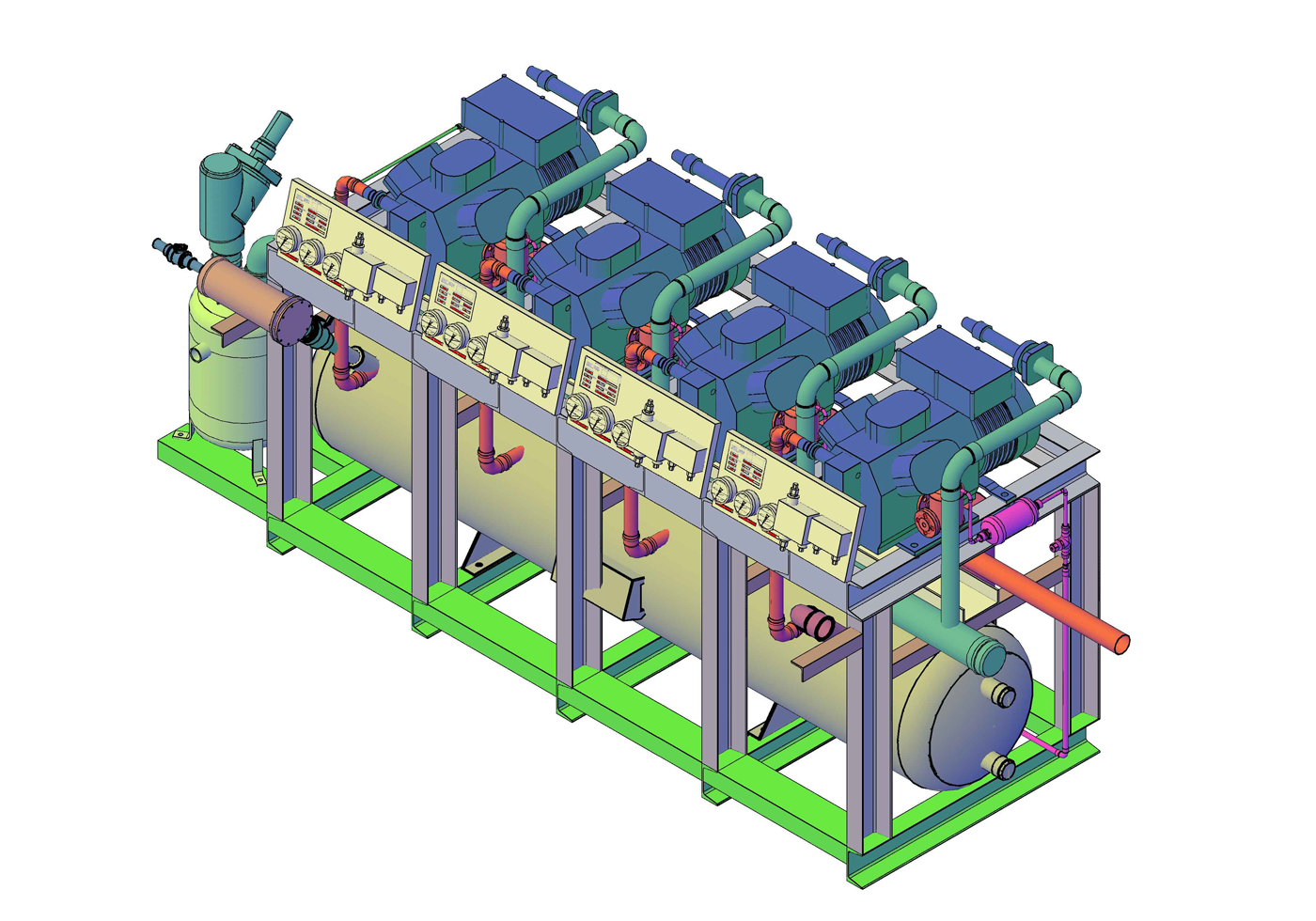

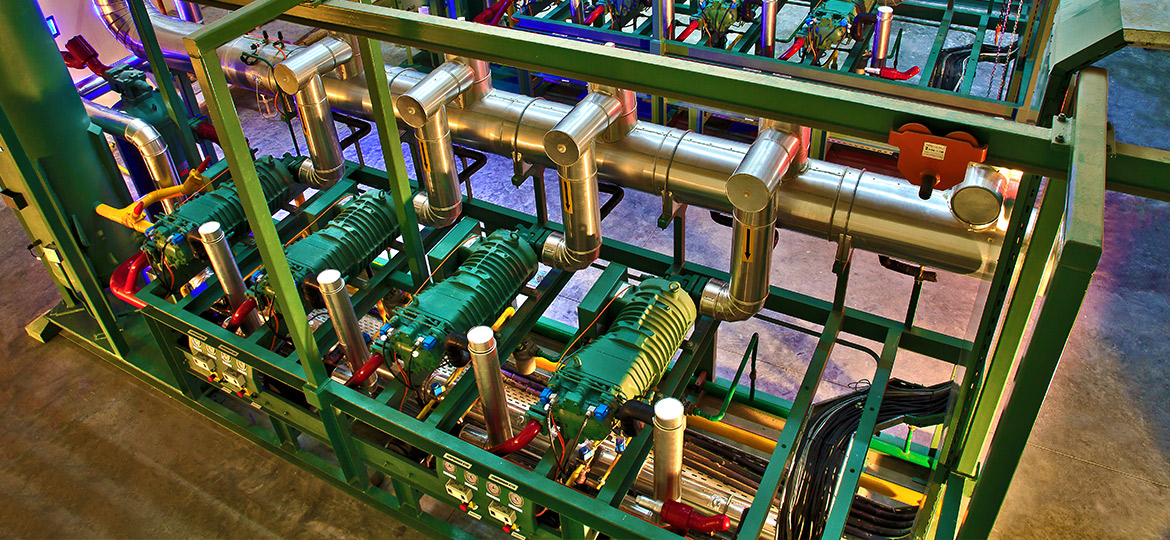

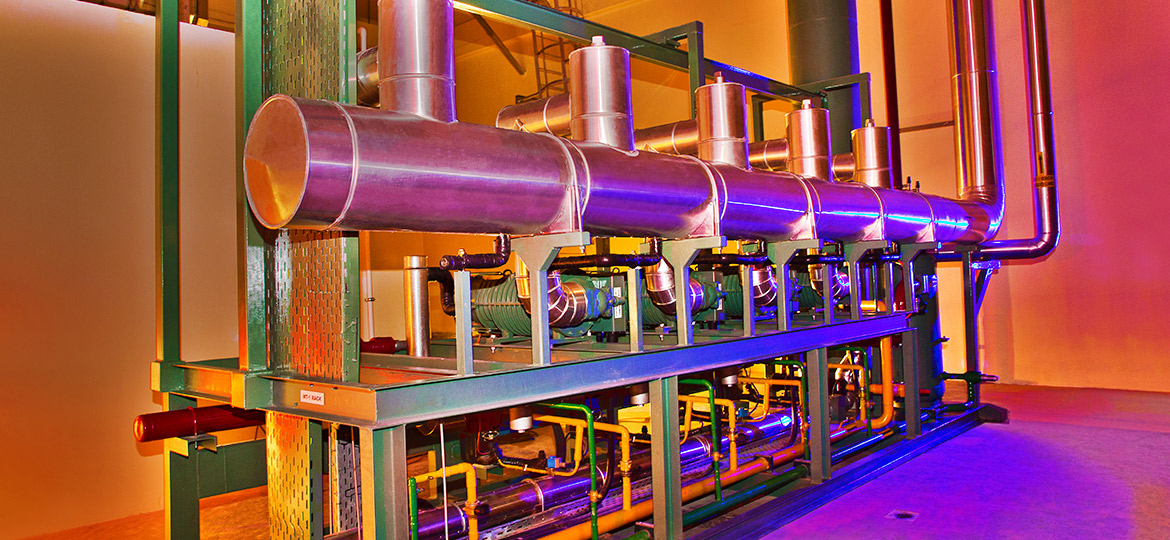

Skid And Rack Packages

Innovation built on strong roots

We provide custom-made turn-key modular process skid systems for any project.

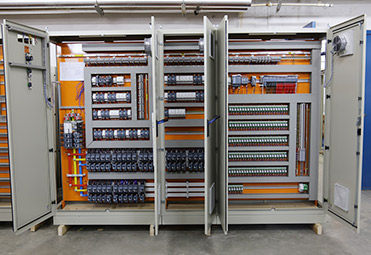

Whether it is for processing, heating or cooling applications, PSI has the in-house capability of manufacturing, fabricating and assembling various components together to provide you with a standard or customized rack to cater to your facility's requirements. Our long-standing relationships with various major component suppliers, combined with our in-house manufacturing of major components - such as pressure vessels, control panels and cladding – ensure that we can provide the highest quality levels for the solutions provided to you.

In-house Capabilities

PSI can comprehensively analyze your designs or create designs for you based on your process requirements. We are high pressure equipment manufacturer that employs advanced methods of design, including stress and fatigue analysis reports and finite element analysis if required.

Ammonia Skid Mounted Packages

Other Skid Mounted Packages

With our experience, we can quickly develop procedures for joining your unique material selection if we do not already have procedures developed for the material you request.